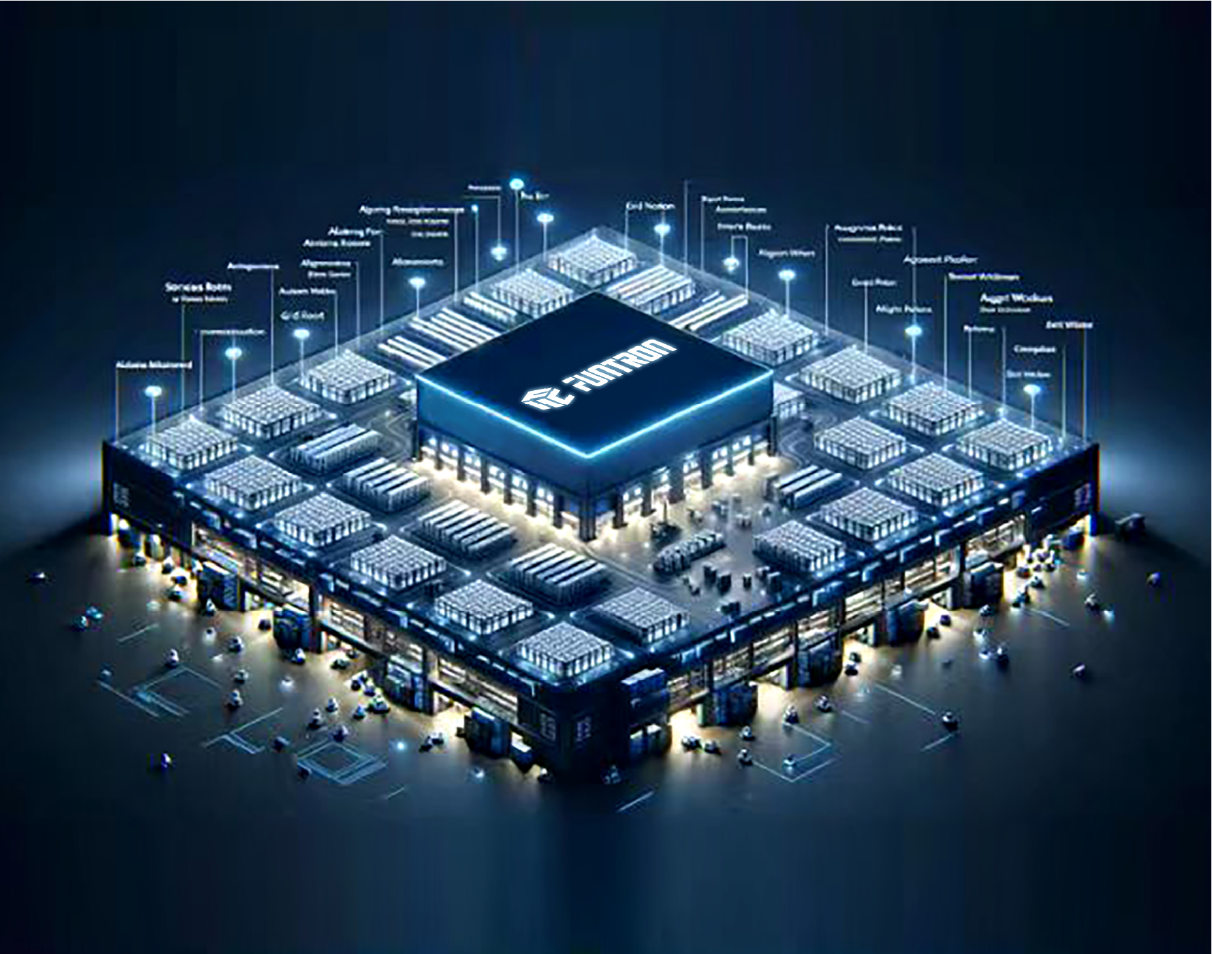

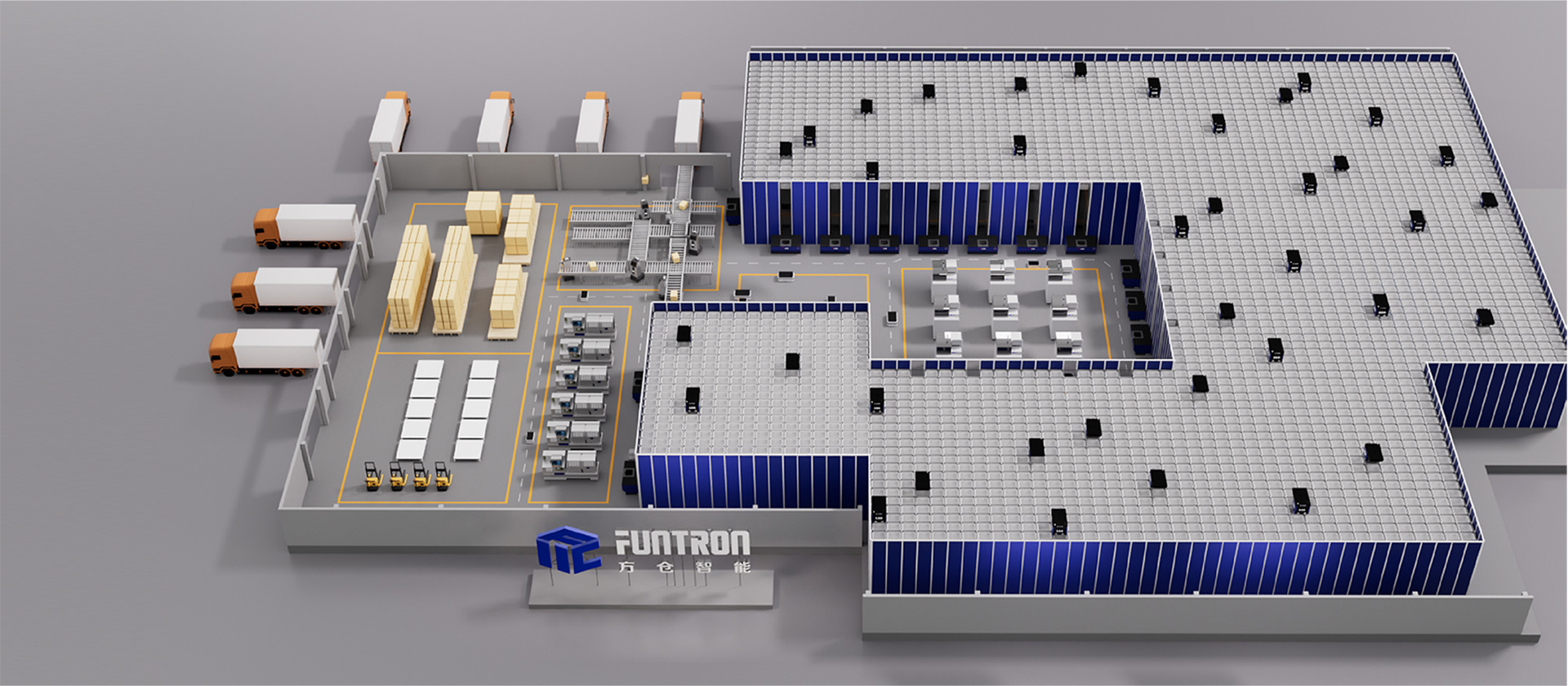

When exploring the transformation and innovation of the manufacturing industry, intelligent warehousing technology has become the core force driving the development of material management field with its unique advantages. With the continuous progress of technology and the deepening development of industrial intelligence trends, intelligent warehousing systems are gradually emerging and becoming a key factor that cannot be ignored in the field of material management in the manufacturing industry.

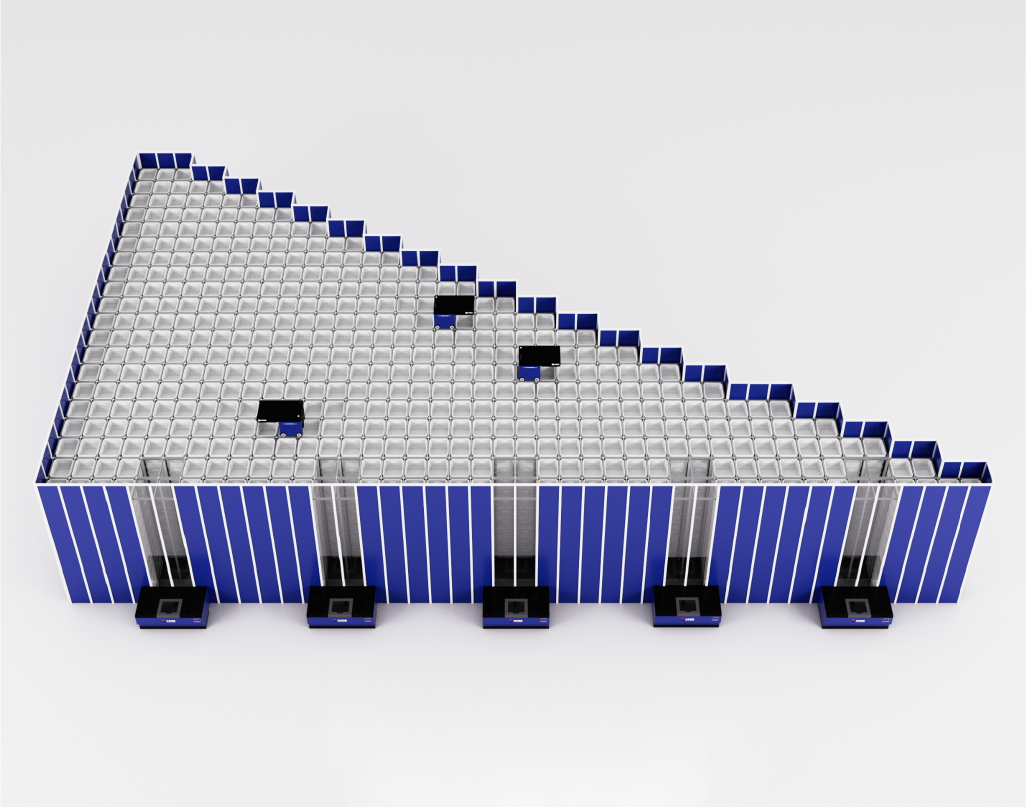

With the continuous progress of the manufacturing industry, the complexity of material management is becoming increasingly prominent, and traditional warehousing management methods are no longer able to meet the high standards of efficiency and accuracy required by modern manufacturing. In view of this, the cubic warehouse intelligent warehousing system has emerged, injecting new management vitality into the manufacturing industry through innovative means of automation, dataization, and intelligence, bringing unprecedented changes in management models.