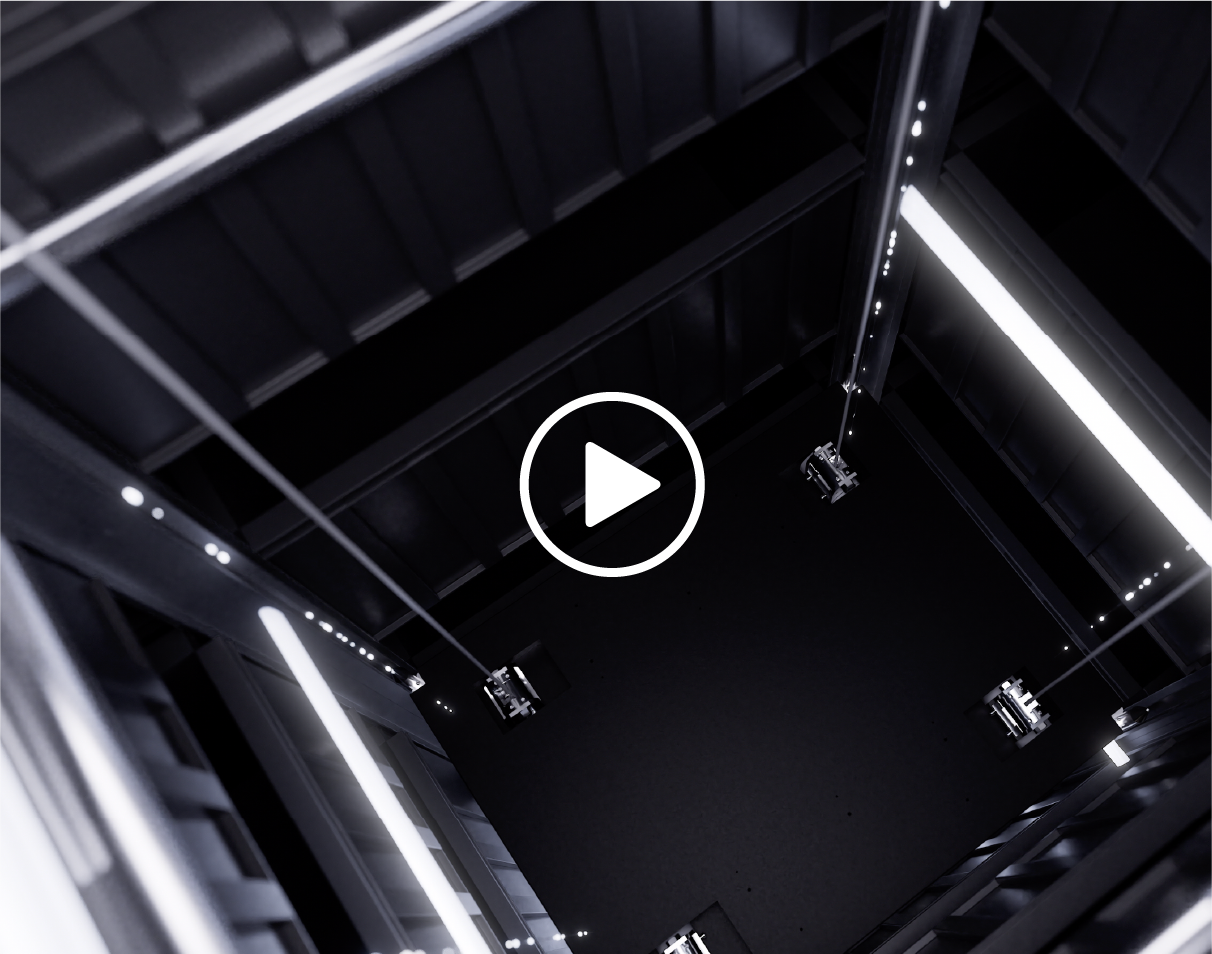

Just a few seconds, you can easily pick up any location of the container, completely subvert the traditional storage pick-up time. With our advanced algorithms, the system is able to intelligently deploy containers based on order data, ensuring the dynamic flow and precise positioning of each box for true real-time extraction. High-frequency containers are automatically optimized to the top layer, reducing unnecessary access to low-frequency containers and directly improving operational efficiency - in fact, more than a third of containers can be accessed without digging.

Funtron algorithm platform, so that your warehousing operations faster, improve business fluency to a new peak!